The lifting sling plays an important role in lifting operations. By definition, a sling is a movable link between a lifting device (crane, etc.) and a load to be lifted. There are three main types of lifting slings on the market: chain slings, textile slings and wire rope slings. The choice of the sling type is crucial for any kind of lifting operation. Thus, the choice of the sling depends on different factors such as the weight, the size, the shape and the accessibility of the load to be lifted.

Chain slings are distinguished by the steel grade: grade 80, 100 or 120. The higher the grade, the stronger the chain slings and the higher the Working Load Limit (WLL) for a given chain diameter. The temperature range of chain slings is also higher than that of other types of slings, so lifting operations can be carried out safely without loss of WLL. (see technical article on temperature ranges).

Heavier than wire rope or textile slings, chain slings are more difficult to handle and can damage the part to be handled in case of direct contact with fragile parts.

Textile slings are lighter and therefore easier to carry and handle. They are also very flexible and therefore allow many different ways of lifting fragile or complex shaped loads.

However, textile slings do not withstand high temperatures, their range of use being between -40° and 100° C. They are also more fragile to mechanical (abrasion and friction) and chemical aggression (acid and basic products).

Different types of protection exist to increase the lifetime of the textile sling: PVC sheaths, polyurethane projections, ….

Consisting of a head ring and a hook, wire rope slings are both flexible and relatively light.

In addition to being resistant to abrasion and high temperatures, these slings are best suited to lift heavier loads and heavy duty installations such as used on construction sites.

However, due to their higher weight, wire rope slings are more difficult to handle and can damage fragile parts. They are also prone to damage from bending, abrasion or crushing. As a result, they need to be checked more regularly.

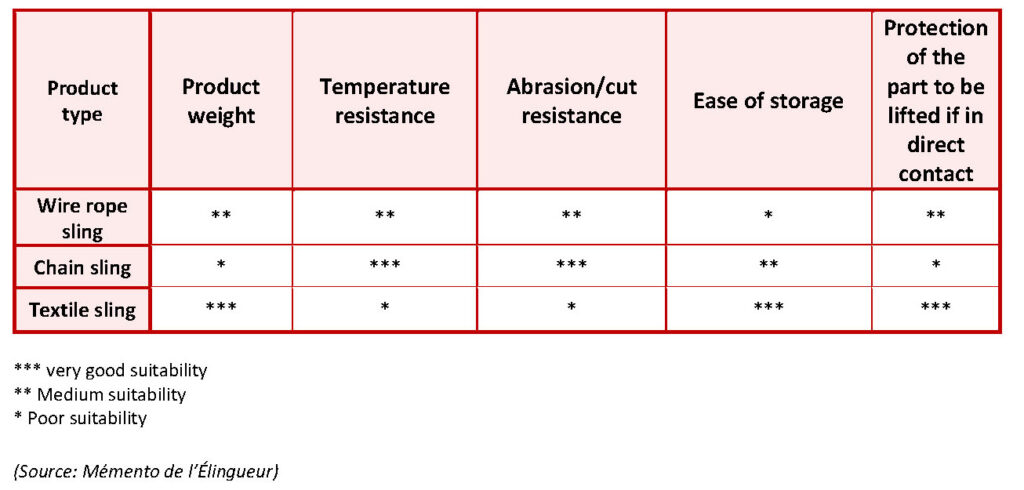

The characteristics of the different types of slings can be summarized as follows:

To determine which sling to choose, a multitude of factors must be taken into account: the temperature of use, the weight, nature and shape of the load to be lifted, the working environment, etc. It is therefore always advisable to contact a technical developer who will guide you towards the right choice of your lifting equipment.